Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

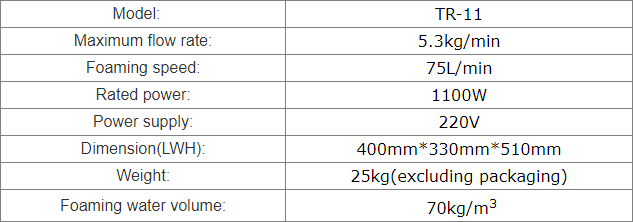

PRODUCT PARAMETERS

Description

TR-11 Foaming machine

TR-11 Foam Machine Introduction:

A foaming machine (also known as foam-generating equipment) is the core equipment of a lightweight concrete preparation system. Its primary function is to convert the proportionally prepared foaming agent aqueous solution into standard foam through a professional process. As the key equipment for foam concrete and foamed cement production, its technical performance directly determines the core indexes such as structural strength, density distribution, and durability of the final products.

Tongrun series of high-pressure foaming equipment adopts advanced airflow mechanics foaming technology, which has the following significant

advantages:

- High-performance production: integrated high-pressure aerodynamic system to achieve industry-leading foaming rate of ≥8m³ foam per minute.

- High-quality foam output: generate bubble diameter 0.1-0.5mm level micro-fine closed-cell foam, pore uniformity of more than 95%.

- Excellent stability: original foam stabilization technology extends foam half-life to 4 hours (ASTM C869 standard).

- Economy and environmental protection: Foam water secretion <3%, foaming agent utilization rate increased by 40%, and comprehensive operating costs reduced by 25%. Research-specific

TR-11 foaming system (power 1.1kW/bright yellow)

This experimental grade equipment is designed for scientific research institutions and engineering verification needs, applicable to:

1. Building materials laboratory: This laboratory collaborates with colleges, universities, and research institutes to develop new lightweight concrete formulations.

2. Small-scale engineering applications: bath backfill, floor heating matting and other renovation projects on-site foaming operations.

3. Trial production scenario: sample preparation and small batch production for small precast component factories.

Important operation specification: Based on the thermodynamic protection mechanism, it is recommended to run continuously for ≤ 20 minutes at a time and cannot be switched on continuously for an extended period so as to ensure the service life of the equipment and the accuracy of the experimental data.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply polyethylene fibre (PVA fibre) all over the world. We have a professional technical department and quality supervision department, a well-equipped laboratory with advanced testing equipment and an after-sales customer service centre. Please send us an email or click on the required product to send an enquiry.

If you want to know more about TR-11 Foaming machine please feel free and contact us: sales1@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

REQUEST A QUOTE

RELATED PRODUCTS

TR-11 Mini Foam Generator for CLC Blocks

Foam Concrete Horizontal Mixer 300L 750L

Polycarboxylate Superplasticizer Container Equipment

industrial design Equipment for making foam Foaming machine

Integrated Machine for Pouring Light Steel Keel and Structural Wall