Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

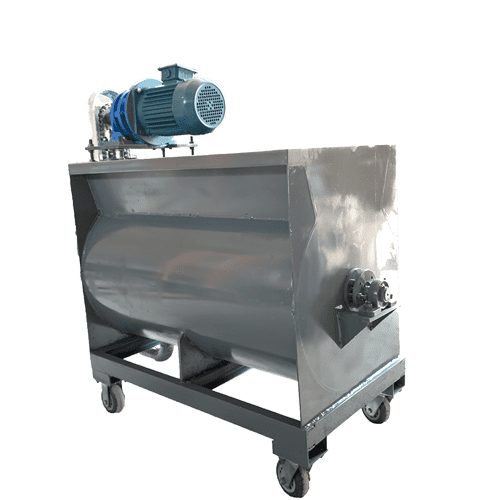

Types of Polycarboxylate Superplasticizer Container Equipment

1. On-site installation equipment (manual, automatic, fully automatic; 5T, 10T, 15T)

2. Container equipment (manual, automatic, fully automatic; 5T)

Features of manual equipment installed on site

There are 5T, 10T, and 15T capacity manually.

- No requirements for the site.

- The high ground is dry, and water and electricity are sufficient. Normal temperature, heating, and normal pressure production processes are all possible.

- Integration of mother liquor synthesis and compounding.

- Fast delivery and use

- No on-site installation; production and debugging can be carried out in real-time upon arrival.

- Low-position feeding design eliminates the need for a steel platform and iseasy to operate. The power-off protection function effectively protects all electrical switches.

- With video, remote monitoring, and intelligent operation. Multi-product production can produce two kinds of mother liquors and can also be compounded production at the same time.

- Fully enclosed, no three wastes are discharged, and production is environmentally friendly. Standard packaging, simple and standardized appearance.

- The main material and paint adopt new materials, which are resistant to corrosion, acid and alkali, and anti-ageing. Special lightning protection design, normal production in thunder and lightning weather.

- Product functions can be adjusted in time to meet the production requirements of early strength, retardation, and slump-preserving superplasticizers.

- All incoming and outgoing goods, water sources, and raw materials are stainless steel quick connectors. Automatic temperature compensation design, normal production in cold seasons, to ensure stable quality.

- Touch LED screen, human-machine friendly interface, real-time display of production status. The special anti-skid electrostatic design further improves the safety performance.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality equipments such as TR-11 Mini Foam Generator for CLC Blocks, TR75 7.5 kW CLC Foam Generator for Lightweight Concrete, TR30 CLC Foaming Machine Concrete Foam Generator, 13kw High Expansion Foam Generator, TR10 Concrete Blocks Making Machine and other concrete relative machines all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs

Q1

What are the materials of polycarboxylate superplasticizer container equipment?

Answer:

The materials of polycarboxylate superplasticizer container equipment usually include stainless steel, carbon steel and plastic. Among them, stainless steel and carbon steel materials have strong corrosion resistance and pressure resistance, and are suitable for storing highly acidic and alkaline water-reducing agents; while plastic materials are lighter and less prone to rust, and are suitable for storing mildly acidic and alkaline water-reducing agents.

Q2

How to choose suitable polycarboxylic acid superplasticizer container equipment?

Answer:

Selecting the appropriate polycarboxylate superplasticizer container equipment requires consideration of factors such as the chemical properties, storage capacity, transportation requirements, and ease of operation of the superplasticizer. At the same time, attention needs to be paid to the sealing performance of the container to ensure the quality and safe storage of the water-reducing agent.

Q3

How to install and use polycarboxylate superplasticizer container equipment?

Answer:

The installation and use of polycarboxylate superplasticizer container equipment needs to be carried out in accordance with the instructions and operating instructions. It is necessary to clean the container and equipment to ensure that there is no residue, and then add an appropriate amount of polycarboxylate superplasticizer. At the same time, attention needs to be paid to the sealing and pressure-bearing capacity of the container to avoid problems such as leakage and excessive pressure.

Q4

How to maintain and maintain polycarboxylate superplasticizer container equipment?

Maintenance and maintenance of polycarboxylate superplasticizer container equipment requires regular cleaning of the inside of the container and inspection of the sealing performance of the container. At the same time, attention should be paid to moisture-proof and sun-proof measures for container equipment to avoid long-term exposure to moisture and sunlight.

Q5

What are the common faults of polycarboxylate superplasticizer container equipment? How to solve?

Answer:

Common failures of polycarboxylate superplasticizer container equipment include container leakage, valve damage, pumping system failure, etc. For container leakage, it is necessary to check whether the sealing ring and the container connection are tight; for valve damage, the damaged valve needs to be replaced; for pumping system failure, it is necessary to check the working status of the pump and whether the pipe connection is tight.

Q6

How to improve the storage effect of polycarboxylic acid superplasticizer container equipment?

Answer:

To improve the storage effect of polycarboxylic acid superplasticizer container equipment, it is necessary to keep the container clean and sealed to avoid external contamination and air intrusion. At the same time, it is necessary to pay attention to the temperature and humidity of the storage environment to avoid deterioration of the water-reducing agent caused by excessive temperature or excessive humidity.

Q7

How to ensure the transportation safety of polycarboxylate superplasticizer container equipment?

Answer:

To ensure the transportation safety of polycarboxylate superplasticizer container equipment, you need to choose the appropriate transportation method and appropriate packaging container. At the same time, attention needs to be paid to avoiding severe vibrations and collisions during transportation and maintaining the stability and integrity of the container.

REQUEST A QUOTE

RELATED PRODUCTS

TR-20 Lightweight Concrete Machine

TR30 CLC Foaming Machine Concrete Foam Generator

industrial design Equipment for making foam Foaming machine

industrial design Equipment for making foam Foaming machine

industrial design Equipment for making foam Foaming machine