Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Superplasticizer

Instant Potassium Silicate

Lightweight concrete nano-modifier

Naphthalene based Superplasticizer Concrete Admixture SNF Superplasticizer

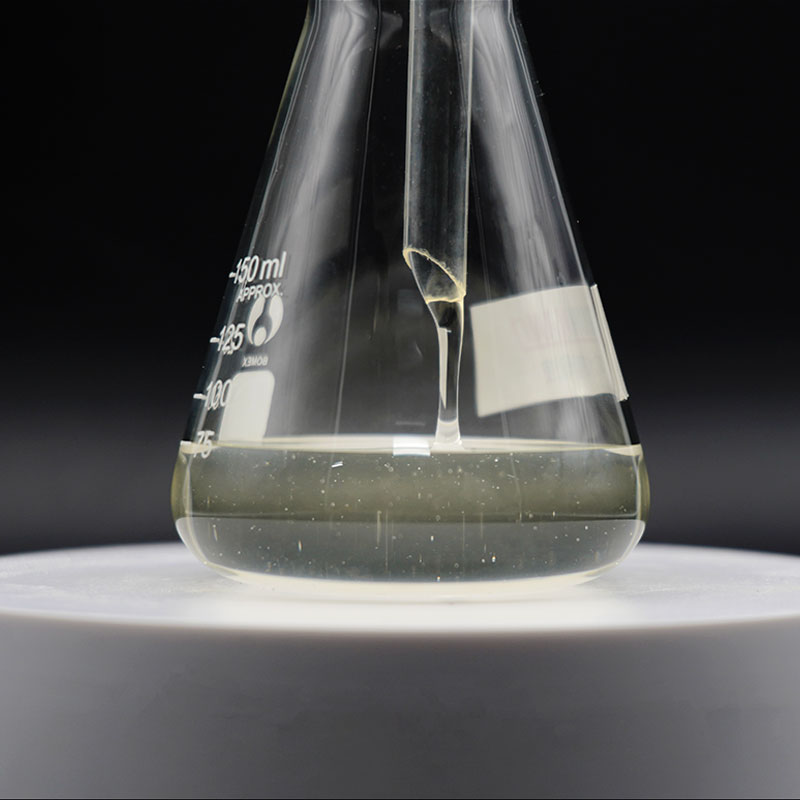

Polycarboxylate Superplasticizer Liquid olycarboxylic Acid High Performance Liquid Water Reducing Agent

Polycarboxylate Superplasticizer Liquid Polycarboxylic Acid High Performance Water Reducing Agent Early Strength Type Liquid Concrete Water Reducing Agent

Polycarboxylate Superplasticizer Liquid Polycarboxylic Acid High Performance Water Reducing Agent Slow Setting Type Liquid Concrete Water Reducing Agent

Polycarboxylic Acid High Performance Powder Water Reducer Polycarboxylate Superplasticizer Powder

Concrete Superplasticizer Overview

A water reducer is a concrete admixture that can reduce the amount of mixing water while maintaining the slump of concrete basically unchanged. Concrete mixture has a dispersing effect on cement particles, which can improve its workability, reduce the unit water consumption, improve the fluidity of concrete mixture; or reduce the unit cement consumption and save cement.

Types of water reducers

According to performance, it can be divided into ordinary water reducer, high-efficiency water reducer, and high-performance water reducer.

1) Ordinary water reducer refers to an admixture with a water reduction rate of not less than 8% under the condition that the slump of concrete is basically the same.

2) High-efficiency water reducer refers to an admixture with a water reduction rate of not less than 14% under the condition that the slump of concrete is basically the same.

3) High-performance water reducer refers to an admixture with a water reduction rate of not less than 25% under the condition that the slump of concrete is basically the same. Compared with high-efficiency water reducers, it has good slump retention performance, small drying shrinkage and certain air entrainment performance.

Due to the important contribution of high-efficiency water reducer to concrete modification, its application has become the third breakthrough in the history of concrete development after reinforced concrete and prestressed concrete, which has enabled concrete to develop from the original manual pouring or hanging tank pouring to pumping construction, saving manpower, improving work efficiency, ensuring quality, eliminating noise, and making a great leap in the technical level and construction level of concrete.

Mechanism of action of water reducer

1) Dispersion

After the cement is mixed with water, the cement slurry forms a flocculation structure, and 10% to 30% of the mixing water is wrapped in the cement particles and cannot participate in free flow and lubrication, thus affecting the fluidity of the concrete mixture. When the water reducer is added, the water reducer molecules can be directional adsorbed on the surface of cement particles so that the surface of cement particles carries the same charge (usually negative charge), forming an electrostatic repulsion effect, prompting the cement particles to disperse each other, the flocculation structure to disintegrate, and release the wrapped part of the water to participate in the flow, thereby increasing the fluidity of the concrete mixture.

2) Lubricating effect

The hydrophilic group in the water reducer is very polar. The water reducer adsorption film on the surface of cement particles can form a stable solvated water film with water molecules. This water film has a good lubricating effect and can effectively reduce the sliding resistance between cement particles so that the fluidity of concrete is further improved.

3) Steric hindrance

The hydrophilic side chains in the water reducer structure extend in the aqueous solution and form a hydrophilic three-dimensional adsorption layer of a certain thickness on the surface of the adsorbed cement particles. When the cement particles are close, the adsorption layers begin to overlap, that is, steric hindrance occurs between the cement particles. The more overlaps, the greater the steric repulsion and the greater the hindrance to the cohesion between cement particles so that the concrete maintains a good slump.

4) Slow-release effect of grafted copolymer side chains

During the preparation process of new water reducers, such as polycarboxylic acid water reducers, some side chains are grafted on the molecules of the water reducer. The side chains can not only provide a steric hindrance effect but also be slowly cut off in the high alkalinity environment of cement hydration, releasing polycarboxylic acid with a dispersing effect so as to improve the dispersion effect of cement particles and control the slump loss.

Why does concrete need to reduce water?

A key parameter of the concrete mix ratio is the water-cement ratio, that is, the ratio of water to cementitious material. The higher the water-cement ratio, the better the workability of fresh plastic concrete, the easier it is to construct, but the lower the strength of concrete. In order to solve this contradiction, a water reducer needs to be added to improve strength without sacrificing workability or to reduce cement dosage while maintaining workability and strength.

The essential function of a water reducer is to reduce the water consumption of concrete, and it is one of the indispensable raw materials for concrete materials. The strength of concrete is closely related to the water-cement ratio. At a certain slump, the smaller the water consumption, the higher the strength. Adding a water reducer can reduce water consumption while keeping the slump unchanged, thus improving the strength of concrete.

In the low strength grade range below C30, the use of a water reducer can reduce cement consumption, reduce costs, and improve the workability of plastic concrete.

In the medium strength grade range of C40 to C50, a water reducer is generally required to ensure the workability (pumping) and strength of concrete.

For the high strength grade range above C50, without the use of a high-efficiency or high-performance water reducer, the concrete has basically no workability and cast-in-place concrete is difficult to construct.

Pumped concrete should be mixed with a pumping agent or water reducer, and mineral admixtures should be added; a high-performance water reducer with a water reduction rate of not less than 25% should be used for high-strength concrete above C60; mineral admixtures and slow-setting water reducer should be added to large-volume concrete.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012's.

We can supply high-quality superplasticizer such as Naphthalene Superplasticizer, HPEG 2400 Polycarboxylate Superplasticizer, High slump retaining type polycarboxylate superplasticizer admixture, Polycarboxylate Ether superplasticizer and other Concrete superplasticizer all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Polycarboxylate Superplasticizer, please feel free and contact us: sales@cabr-concrete.com

Package of Polycarboxylate Superplasticizer Powder

25Kg woven outer bag lined with plastic bag, stored at room temperature away from light, moisture and rain.

Storage of Polycarboxylate Superplasticizer Powder

Paper plastic composite packaging lined with plastic bags

FAQs of Concrete Superplasticizer

Q: Just how do superplasticizers function?

A: Superplasticizers work by dispersing concrete particles, minimizing inter-particle rubbing and allowing the mix to move more freely with less water.

Q: Can superplasticizers be utilized with all types of concrete?

A: The majority of superplasticizers are compatible with standard sorts of cement, but compatibility with details blends should be evaluated to make certain optimum efficiency.

Q: Are there any kind of disadvantages to utilizing superplasticizers?

A: While useful, superplasticizers can sometimes create problems such as enhanced blood loss if excessive used or postponed establishing times. Proper does and blending techniques are necessary.

Q: How do I store superplasticizers?

A: Store superplasticizers in a great, dry location, shielded from direct sunshine and cold temperatures. Follow manufacturer standards for best outcomes.

Q: What is the life span of a superplasticizer?

A: Life span differs depending on the kind and storage space conditions however normally ranges from 6 months to a year. Constantly examine the producer's referrals.