Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

Introduction of Early Strength Type Polycarboxylate Superplasticizer Liquid

Polycarboxylate Superplasticizer (early-strength type) is an early-strength high-performance water-reducing agent independently developed by our company. The main component of superplasticizer is synthesized using new polyether monomers through molecular structure design and grafting processes. A kind of early-strength polycarboxylate superplasticizer compounded with other functional production additives. The use of superplasticizer can significantly reduce the water-cement ratio, improve the working performance of concrete, and make the concrete have high density and volume stability. The use of superplasticizer can promote the development of early strength of concrete, shorten the steam curing time of concrete or even eliminate the steam curing link, thereby greatly improving production efficiency and saving energy consumption, and can significantly improve the early, mid-term and late strength of concrete.

Polycarboxylate Superplasticizer (early strength type) is suitable for the concrete precast component industry, such as the concrete pipe pile industry, prefabricated concrete precast components, and other concrete precast components.

Features of Early Strength Type Polycarboxylate Superplasticizer Liquid

High water reduction rate: Within the commonly used dosage range, the saturated water reduction rate can reach 40%.

High workability: It can effectively increase the fluidity of concrete and reduce bleeding and segregation, thereby improving the workability of concrete and making it easier to construct and compact. The resistance during pumping construction is small and easy to transport.

Early strength performance: The 1d, 3d, and 7d compressive strengths of concrete prepared with the polycarboxylic acid high-performance water-reducing agent (early strength type) can be increased by more than 90%, 80% and 65% compared with the benchmark concrete.

High durability: Increase the density of concrete and significantly improve the impermeability, frost resistance and carbonation resistance of concrete.

Low shrinkage rate: The 28-day shrinkage rate of hardened concrete is 20% lower than that of the second-generation water-reducing agent, which can significantly reduce the shrinkage of concrete and improve the volume stability and durability of concrete.

Strong adaptability: good compatibility with various types of cement, fly ash, slag and other admixtures.

Good stability: no stratification, no precipitation during long-term storage, and no crystallization in winter.

High economy: It can reduce cement consumption by 20% and reduce the comprehensive project cost.

Green and environmentally friendly: non-toxic, non-irritating, non-radioactive, non-flammable and non-explosive dangerous goods, and will not cause corrosion of steel bars.

Parameters of Early Strength Type Polycarboxylate Superplasticizer Liquid

| Technical indicators | Standard requirements | Test results | |

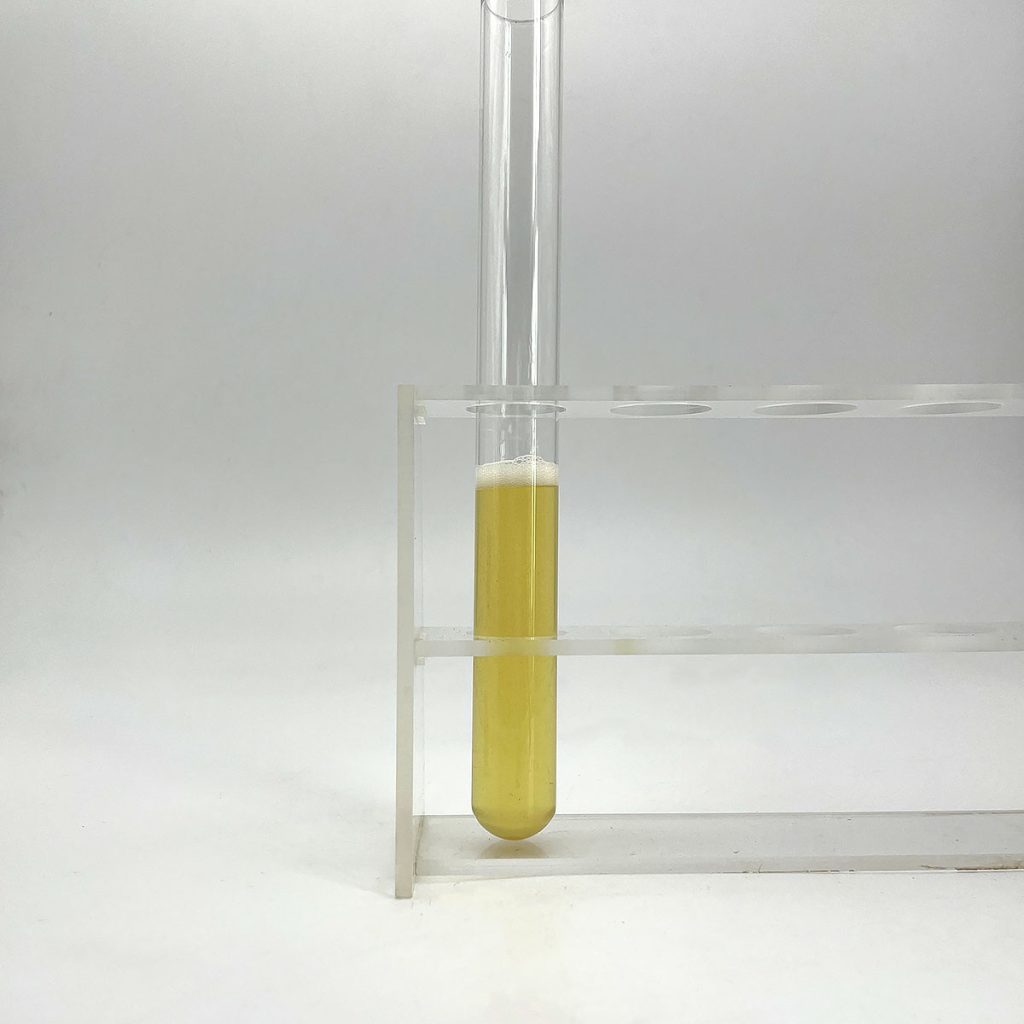

| Appearance | Transparent liquid | Transparent liquid | |

| Water reduction rate/% | ≥25 | 29 | |

| Water seepage rate/% | ≤50 | 15 | |

| Chloride ion content/% | ≤0.10 | 0.01 | |

| Total alkali content (Na2O+0.658K2O)/% | ≤10.0 | 0.5 | |

| pH value | 6.0-8.0 | 6.5 | |

| Density/(g/cm3) | 1.03±0.020 | 1.045 | |

| Setting time | Initial setting | -90~+90 | -20 |

| Final setting | -10 | ||

| Compressive strength ratio/% | 1d | ≥180 | 190 |

| 3d | ≥170 | 180 | |

| 7d | ≥145 | 165 | |

| 28d | ≥130 | 148 | |

| Implementation standard: GB/T 8076-2008 “Concrete admixtures” | |||

Instructions for Using Early Strength Type Polycarboxylate Superplasticizer Liquid

1) Depending on the type, dosage and water-binder ratio of cement, it can be adjusted by changing the dosage. The recommended dosage of this product is 2.0%.

2) When this product is mixed with other admixtures, its compatibility and adaptability must be checked first. When replacing admixtures, pay attention to cleaning the storage utensils.

3) After applying this product, the exposed surface of the concrete should be covered with heat insulation, and watering and curing should not be allowed when temperatures are below zero.

4) If there are special requirements for this product, our company can adjust it according to customer materials and requirements.

5) This product is a chemical safety product, but be careful not to accidentally eat it during transportation and use, and avoid contact with the skin and splashing into the eyes. Once this occurs, please rinse with plenty of water and seek medical treatment if necessary.

Applications of Early Strength Type Polycarboxylate Superplasticizer Liquid

Cold Weather Construction: In winter or cold climates, accelerating the setting and strength gain of concrete is crucial to ensure rapid curing and early form removal.

Accelerated Bridge and Road Repairs: For quick repairs and rehabilitation of infrastructure, early strength superplasticizers allow for faster reopening of traffic lanes.

Prefabrication Plants: In precast concrete operations, rapid strength development enables quicker turnover of molds and faster production cycles.

Emergency Construction: During emergencies or urgent construction projects, early strength gain ensures that critical structures can be put into service sooner.

Tunneling and Underground Works: In tunneling, early-strength concrete can be used for shotcrete linings and other applications where quick setting is necessary for safety and progress.

High-Performance Concrete: For high-strength concrete applications where early strength is a requirement, these admixtures are indispensable.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality superplasticizer such as Naphthalene Superplasticizer, HPEG 2400 Polycarboxylate Superplasticizer, High slump retaining type polycarboxylate superplasticizer admixture, Polycarboxylate Ether superplasticizer and other Concrete superplasticizer all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Early Strength Type Polycarboxylate Superplasticizer Liquid, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Early Strength Type Polycarboxylate Superplasticizer Liquid

1) This product is packaged and transported in sealed ton barrels or 200-liter plastic barrels;

2) This product should be stored in a sealed manner, not mixed with other chemical products, and protected from sunlight. The storage temperature should be above 0°C, and the shelf life is six months at room temperature;

3) If the shelf life is exceeded, it can only be used after being tested and tested by professional engineers. Waste products can be disposed of as ordinary chemicals.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Early Strength Type Polycarboxylate Superplasticizer Liquid

Q: Can early strength superplasticizers be used in all types of concrete?

A: While generally applicable, the suitability of early strength superplasticizers depends on the specific mix design and project requirements. Testing is advisable to ensure compatibility with the cement type, aggregates, and other admixtures.

Q: Does the use of an early strength superplasticizer affect the ultimate strength of the concrete?

A: No, properly selected early strength superplasticizers should not negatively impact the ultimate strength of the concrete. They are formulated to enhance early strength without sacrificing the final strength and durability.

Q: Are there any environmental benefits to using early strength superplasticizers?

A: Yes, by enabling faster curing and reducing the overall curing period, early strength superplasticizers can contribute to more efficient construction practices, potentially reducing the carbon footprint of projects.

Q: How do I determine the correct dosage of an early strength superplasticizer?

A: Dosage varies based on the specific product, the concrete mix design, and the desired performance. Manufacturers typically provide guidelines, but adjustments may be necessary based on trial mixes and field conditions.

Q: Can early strength superplasticizers be used in hot weather conditions?

A: While these admixtures are primarily designed for cold weather, they can be used in hot weather with considerations for the concrete’s thermal mass and hydration rates. Proper hydration control and placement strategies are important.

Q: Are there any safety precautions I should take when handling early strength superplasticizers?

A: Yes, handle these chemicals with appropriate personal protective equipment (PPE). Avoid skin and eye contact, and in case of exposure, rinse thoroughly with water and seek medical advice. Store in a cool, dry place away from incompatible materials.

Q: How do I dispose of unused or expired early strength superplasticizer liquid?

A: Dispose of the product according to local regulations concerning hazardous waste. Do not pour it down drains or into the environment. Consult with your local waste management authority for proper disposal instructions.

REQUEST A QUOTE

RELATED PRODUCTS

Polycarboxylate Superplasticizer Liquid olycarboxylic Acid High Performance Liquid Water Reducing Agent

Instant Potassium Silicate

Naphthalene based Superplasticizer Concrete Admixture SNF Superplasticizer

Lightweight concrete nano-modifier

Polycarboxylate Superplasticizer Liquid Polycarboxylic Acid High Performance Water Reducing Agent Slow Setting Type Liquid Concrete Water Reducing Agent